Alistair Paulls

Member

- Boat name

- CILAOS

- Berth

- Granton

- Boat type

- Moody 333

- Cruising area

- Scotland East Coast

Evening everybody - we're first time buyers looking for some advice on a potential purchase; specifically if the cracks shown below are a red flag and we should walk away, or if it's something we shouldn't worry about. Any help would be really, really appreciated!

The boat is a Moody 27 bilge keel which has been on the hard for the last couple of years near where we live and is on for a fair price compared to others seen online. We went to check it out ourselves (as the marina is open to the public) and have seen a few things which we're not sure about.

Happy to provide any more information which could help - whilst we've tried reading up online to find the answer, we're struggling to know how serious this is. My gut feel is to walk away, but I'm far, far away from really knowing about these thing properly....

Thanks a lot for any help!

The boat is a Moody 27 bilge keel which has been on the hard for the last couple of years near where we live and is on for a fair price compared to others seen online. We went to check it out ourselves (as the marina is open to the public) and have seen a few things which we're not sure about.

- The keels have a large amount of rust on them, but after closer inspection it appears it's only on the surface and looks like it could be easily sanded off, so I think that part is ok.

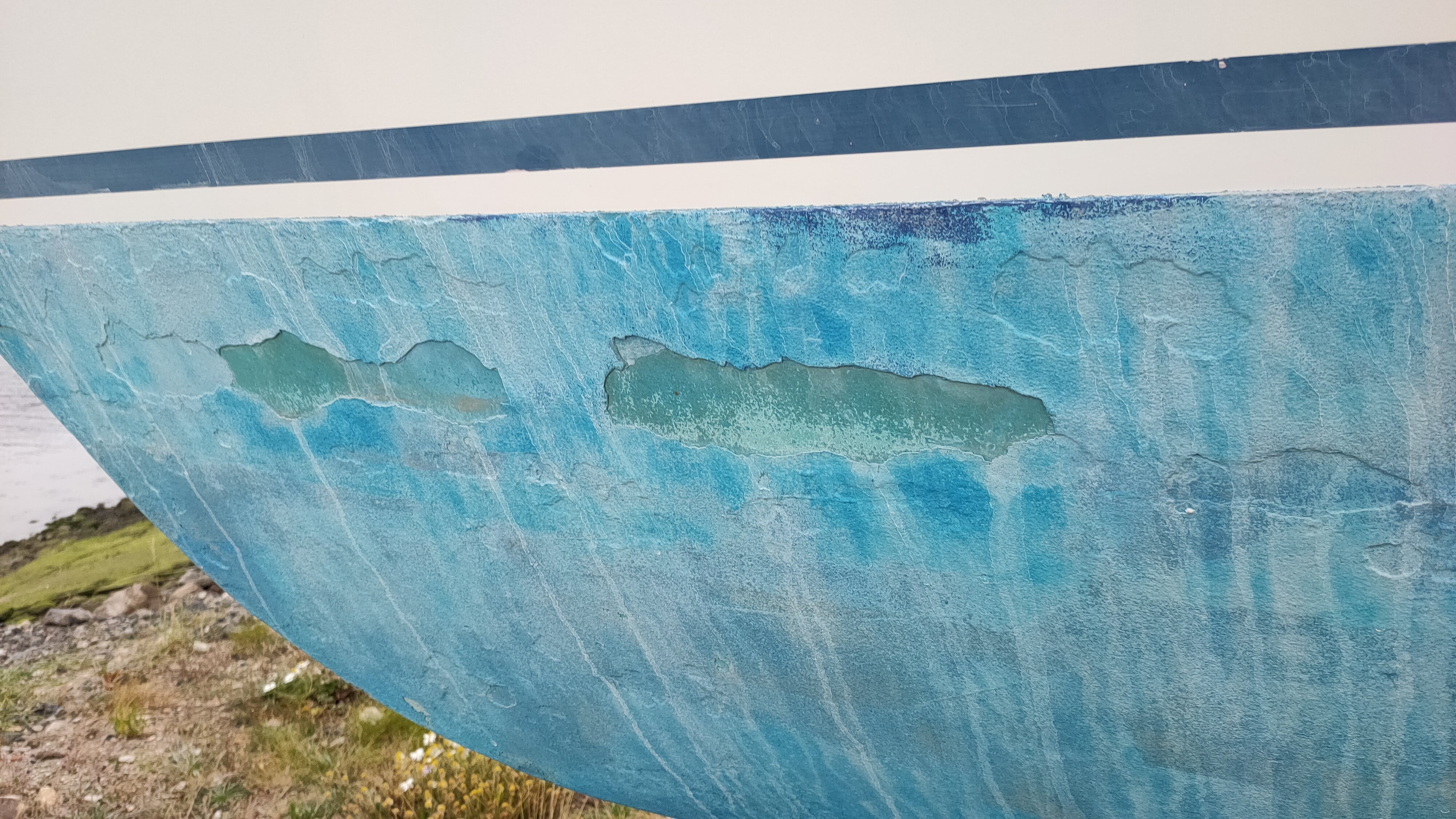

- You can see from the side of the hull, various parts of the antifoul has come off. Could this this be a sign of an osmosis bubble which has dried out and fallen off, or something else? I don't know if as the boat has had a couple of years to dry out you'd still be able to see any osmosis bubbles if they were present?

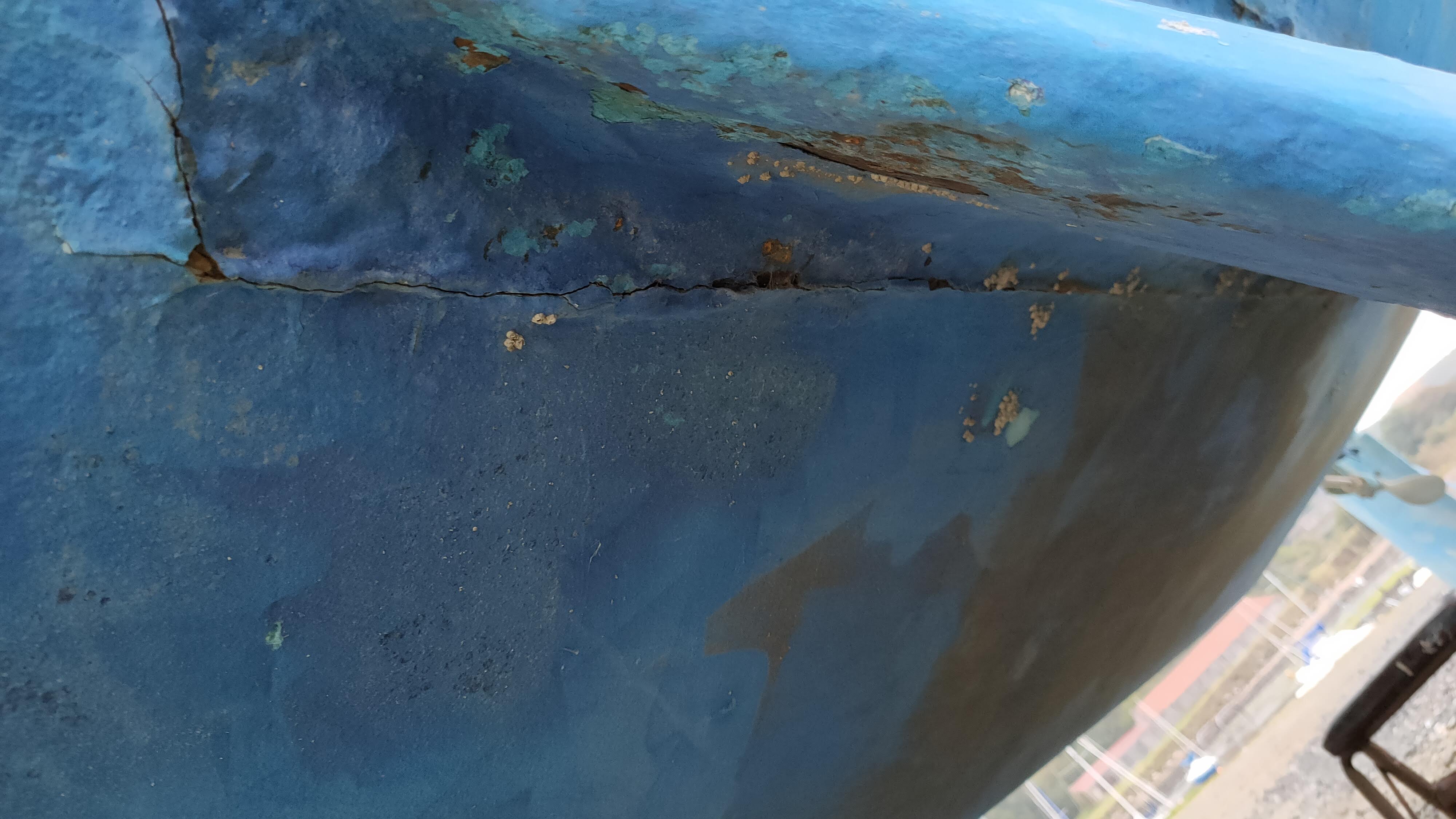

- Finally, and most importantly, there are cracks all along the length of where the keels join the hull. I've no idea if this is simply where filler between the keel and hull has failed, and all that's needed is to fill it in again, or a symptom of something much worse? If water has been getting in there, could this mean the join between the keel and hull has been compromised and both keels would need to be removed and reseated? Would new keel bolts be needed? Anything else???

Happy to provide any more information which could help - whilst we've tried reading up online to find the answer, we're struggling to know how serious this is. My gut feel is to walk away, but I'm far, far away from really knowing about these thing properly....

Thanks a lot for any help!