Hi Peter,

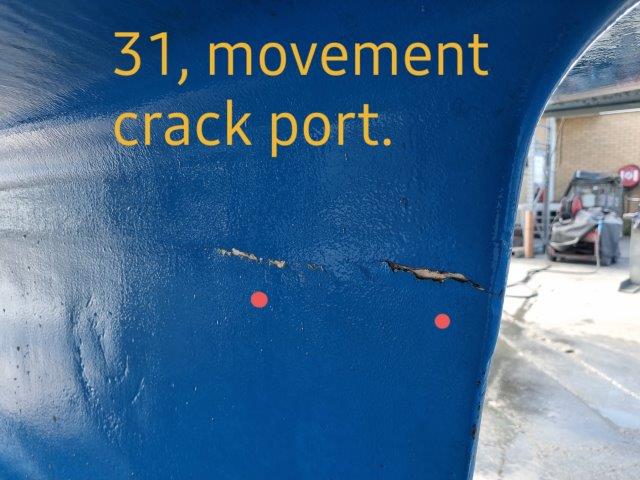

In my personal view, from the photos you have provided, this boat does not have a significant problem. The reason that keel to hull joints are made with a material that dries to a hardish rubber like consistency is that the joint inevitably moves when sailed hard. The exterior cracking, both from corrosion and movement will easily clean up and repaint. The rust ones are in my view, the slightly more concerning - if not attended to, over years the rust can migrate across the top face of the keel to the keel studs, then start them corroding, at which point the only cure is to drop the keel and remake the joint. With the minor rusting shown in your photos, I would grind out the rust as far as practical, repaint any exposed iron with a rust and moisture tolerant epoxy primer replace any joint material lost with Sika 292i or 3M 5200, then replace the antifoul. For the movement cracks, remove any flaked off antifoul and repaint.

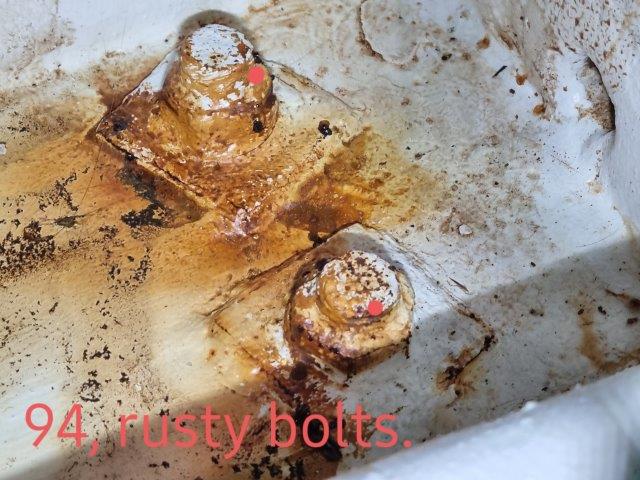

The condition of the stud tops and nuts is remarkably good, bearing in mind that the studs nuts and backing plates are all carbon steel. Marine Projects, who built these boats, avoided stainless steel because of concerns about crevice corrosion. Some corrosion is almost inevitable as salt water gets into the bilge, e.g. when cleaning the log transducer. If their appearance offends you, you could clean them with a wire brush and paint them with a tough, rust tolerant finish such as Hammerite.

Many members have drawn a stud for inspection and they invariably find that the stud below the backing plate is in perfect condition

There is an article on this in our technical library, but I'm not sure that you have access to it as a guest. Temporary membership is not expensive and would convert automatically to full membership for no extra charge if you bought a Moody.

My opinion of the significance of your surveyor's findings is of limited value as it is based entirely on a few photos and I am not a professional marine surveyor.

Peter.